Why Resin Floors Fail. The Truth About Surface Preparation.

As per flooring standards, surface preparation is the main factor regarding success or failure of any resin flooring system. Also, from what I have actually seen on construction sites, no resin will definitely work well if the concrete underneath is not properly prepared. Epoxy and other resins do not stick to concrete itself in a simple manner, and this requires further treatment of the surface. They surely require something to attach themselves to. Moreover, this connection point serves as their anchoring mechanism. When liquid resin flows into small pores of concrete, it creates mechanical grip itself, further working like Velcro system. Without proper grip, the coating itself just sits on the surface and will further come loose due to impact, movement, or temperature changes.

We are seeing that laitance is only the first thing that must be removed. We are seeing this weak, dusty layer that only forms on concrete when it is getting hard. If you apply coating on top, the floor system will surely be only as strong as that weak layer. Moreover, the entire structure depends on this fragile coating for its strength. When vehicles move on it, we are seeing that the weak top layer only breaks and the whole coating peels off. Concrete actually soaks up oils and grease just like a sponge, and these substances definitely break the bonding between materials. You actually need to clean and scrub the surface properly to remove them. This will definitely make it ready for the resin to stick well.

Moisture is actually another big factor that people definitely underestimate often. Trapped moisture itself is the main cause of blistering and bubbling in floors, which further damages the flooring material. Further, that is why proper testing itself matters further for good results. As per standard practice, moisture probes or calcium chloride tests help confirm if the slab is within acceptable limits regarding moisture content. We are seeing that the conditions around us also matter only. The surface temperature should actually stay above the dew point to avoid hidden moisture, and you definitely need to check pH levels because high alkalinity can damage the resin bond over time.

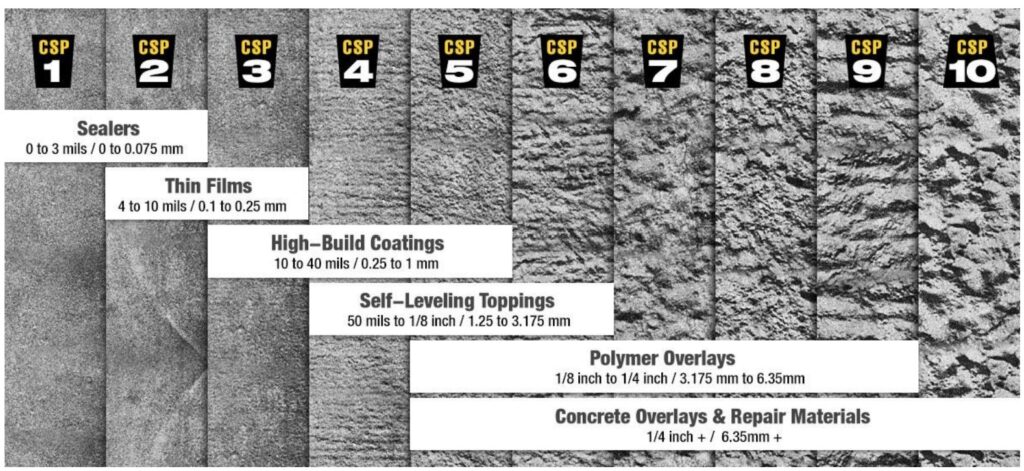

Moreover, getting the correct surface texture is important for the concrete work itself, and this requires further attention to achieve proper results. Thin coatings work better on diamond-ground surfaces, while heavy industrial systems need rougher profiles that shot blasting itself creates. Further, the surface preparation method determines which coating thickness will perform best. When concrete slabs are actually badly damaged or have chemical contamination, you definitely need to scarify and remove the top layer completely. Basically, using proper CSP standards makes the surface rough enough so the floor coating lasts the same 10 to 15 years it should.

For resin flooring, the first few hours of preparation actually decide how well it will perform for years. The initial work definitely determines the long-term quality of the floor. Proper testing and profiling itself may cost more time and money at first, but it further prevents expensive failures later. As per studies, most floor failures do not happen regarding bad materials. Basically, they happen because of the same bad preparation. We are seeing that putting a good floor on bad surface is only like making a building on weak ground.

Let me know your thought, exprience in the comment section.

Contact details : www.linkedin.com/in/sanjay-sadanandan , sanjay@aaa-ron.com +968 91145302.