Smarter Building Envelopes. Balancing R-Value and Emissivity.

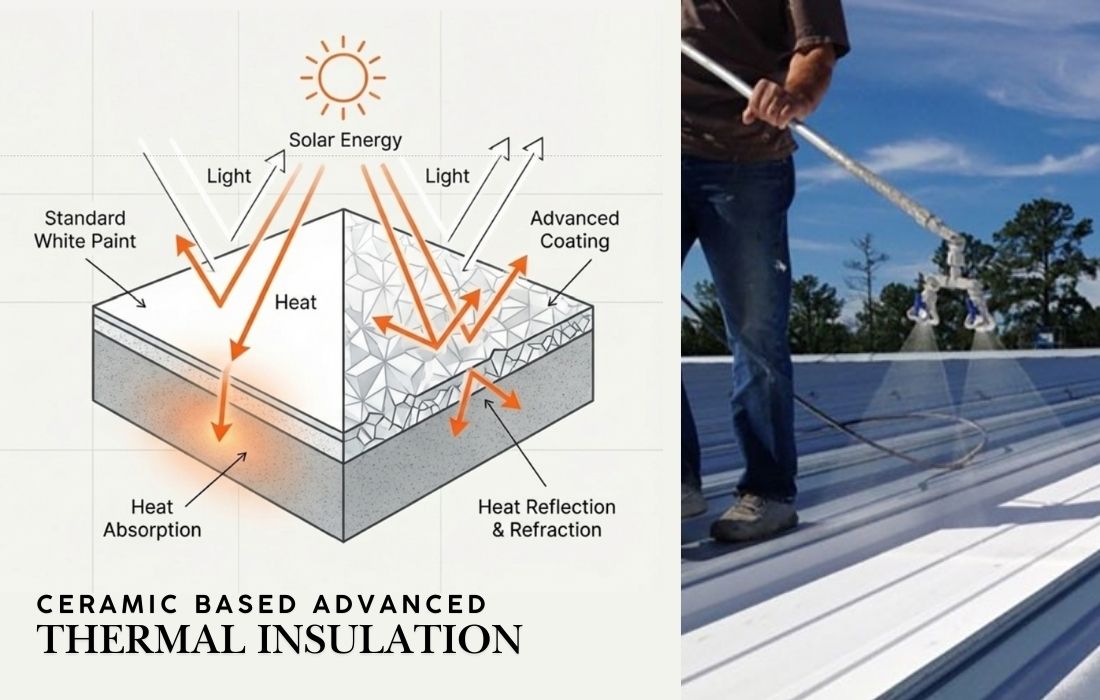

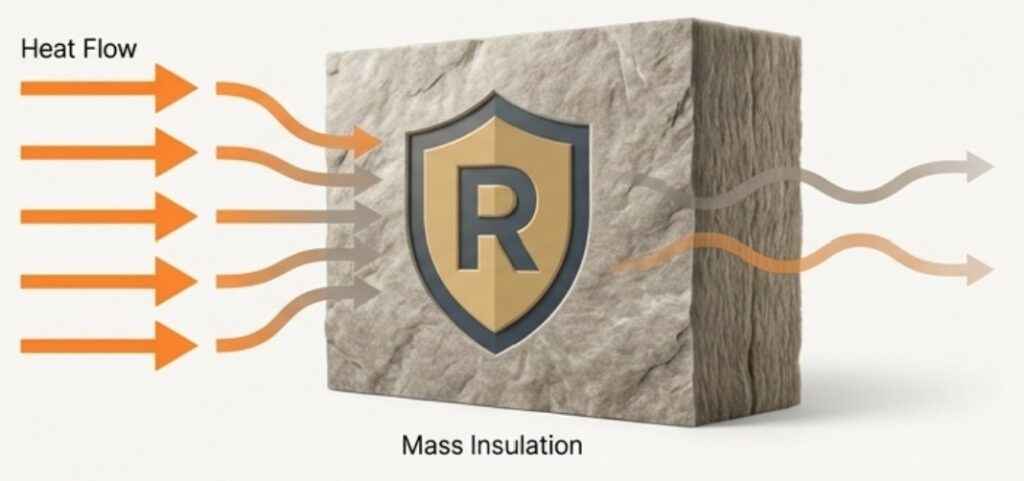

For years, R-value has been treated as the ultimate measure of insulation. It tells us how well a material slows down heat moving through it by conduction. That is important, but it only explains part of the story. Emissivity, or thermal emittance, is about the building’s outer skin. It describes how a surface deals with heat radiation. How much heat it gives off, how much it absorbs, and how it interacts with the environment outside

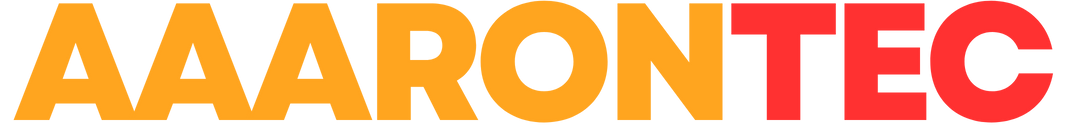

Think of it this way. R-value works through thickness and mass. The material absorbs heat, holds it for a while, and delays its movement. Emissivity is different. It is a surface behavior that decides whether heat is reflected away or allowed to load into the structure in the first place. Traditional insulation behaves like a sponge. It soaks up heat until it is saturated. High-performance surface treatments act more like a shield. They try to stop the heat before it ever gets inside.

Materials such as fiberglass or mineral wool depend heavily on high R-values, but this number has some serious limitations in real life. R-value tests are usually done in controlled lab conditions. About 24°C, no wind, no moisture, and perfectly dry air. Buildings in the real world are nothing like that. Add just 1.5 percent moisture, and the effective R-value can drop by around 35 percent. Wind moving through cavities can also wash away the trapped air that these materials rely on. So an R-value that looks great on paper can fall apart on site, leading to far more heat gain or loss than expected.

This is where surface properties like emissivity and solar reflectance come in. They tackle radiant heat, which R-values largely ignore. Low-emissivity materials, such as metallic radiant barriers, can reflect up to 97 percent of incoming infrared radiation, stopping heat before it enters the building. On the other hand, high-emittance “cool” coatings, often made with hollow ceramic microspheres, reflect most of the solar radiation and quickly release any heat they do absorb. The result is an exterior surface that stays close to ambient temperature. This also helps the insulation behind it stay dry and work under more stable conditions.

The most energy-efficient buildings do not choose between R-value and emissivity. They use both. R-value is still essential for controlling conductive heat flow from inside to outside. But emissivity and reflectance dominate how the building skin performs under strong sun and harsh weather. When you combine bulk insulation with smart surface coatings, you address conduction, convection, and radiation together. This layered approach creates a tougher, more reliable building envelope that performs well even when moisture, wind, and extreme temperatures come into play.

I would love to hear your thoughts on this in the comment section. Have you seen situations where R-value looked good on paper but failed on site, or where surface treatments made a noticeable difference in real performance?

For further queries please contact me at sanjay@aaa-ron.com – Whatsapp/ Cell : 00968 91145302.